Support & Documents

Valve Information

Important Valve Instructions

Curtis Valves that use a special flat molded seal, can not be overhauled. If the valve is leaking, clean the seal area and recheck for leakage. If the valve continues to leak, replace the entire valve per the aircraft maintenance schedule. Curtis valves have a life expectancy of 10 years under normal operating conditions.

Recommended Valve Thread Sealant

We recommend the following thread sealant for Curtis valves:

- Pipe threads – 1/4” teflon tape, Permatex 80632 Thread Sealant, Loctite 592 PST Pipe Sealant

- Straight Threads – Lubricating Oil

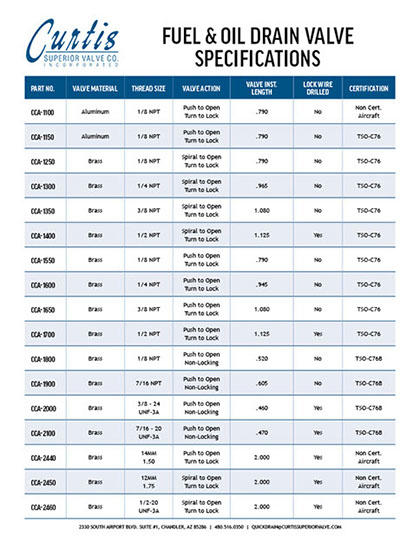

Curtis Valves Applications, Specifications & OEM Cross Reference Information

Reference the Curtis valve torque specs listed on this page for pipe thread valves, straight thread valves and valves with special threads requiring crush washers.

Please see the application information and you can download PDF charts below.

Torque Specifications

Pipe Threads

| 1/8 – 27 NPT | 40 – 45 In. Lbs |

| 1/4 – 18 NPT | 80 – 85 In. Lbs |

| 3/8 – 18 NPT | 105 – 115 In. Lbs |

| 1/2 – 14 NPT | 155 165 In. Lbs |

Straight Threads

| 3/8 – 24 | 80 – 85 In. Lbs |

| 7/16 – 20 | 80 – 85 In. Lbs |

| 1/2 – 20 | 80 – 85 In. Lbs |

| 9/16 – 18 | 80 – 85 In. Lbs |

| 3/4 – 16 | 80 – 90 In. Lbs |

| 5/8 – 18 | 100 – 115 In. Lbs |

Special Threads with Crush Washers

| CCA-2450 12 MM 1.75 | 60 – 70 In. Lbs |

| CCA-2460 1/2 – 20 | 60 – 70 In. Lbs |

| CCA-2470 12 MM 1.75 | 60 – 70 In. Lbs |

| CCA-2480 1/2 – 20 | 60 – 70 In. Lbs |

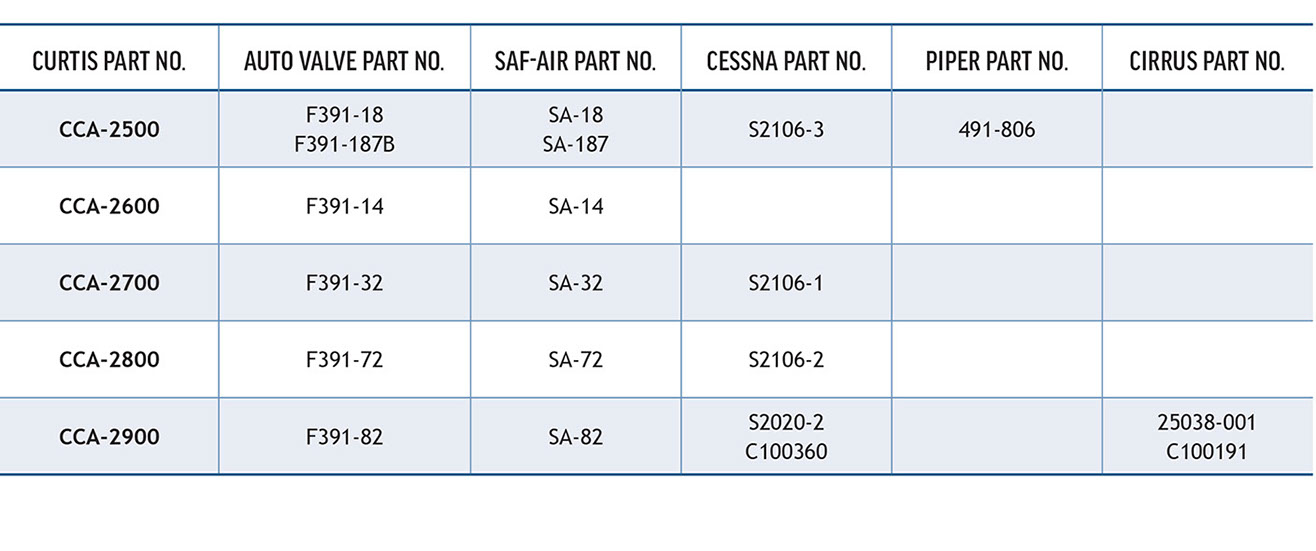

Application & Cross Reference

View or download (PDF) Curtis Valves aircraft engine support documents and information charts.

Flush Fuel Valves OEM & Manufacturers Cross Reference