Products

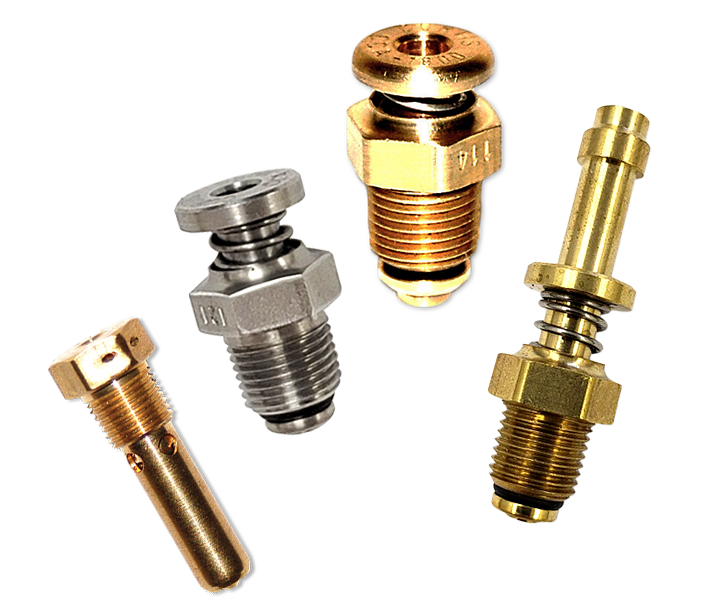

Aircraft Fuel Drain Valves

Flush Mount, Hose Barb, Push Button, T-Handle

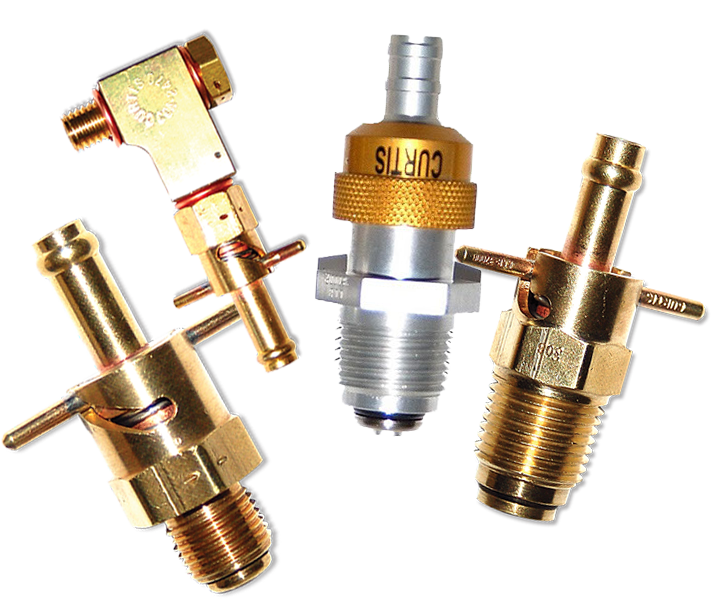

Aircraft oil drain valves

Continental, HKS, Jabiru, Lycoming, Rotax

Aircraft oil drain valves

Continental, HKS, Jabiru, Lycoming, Rotax

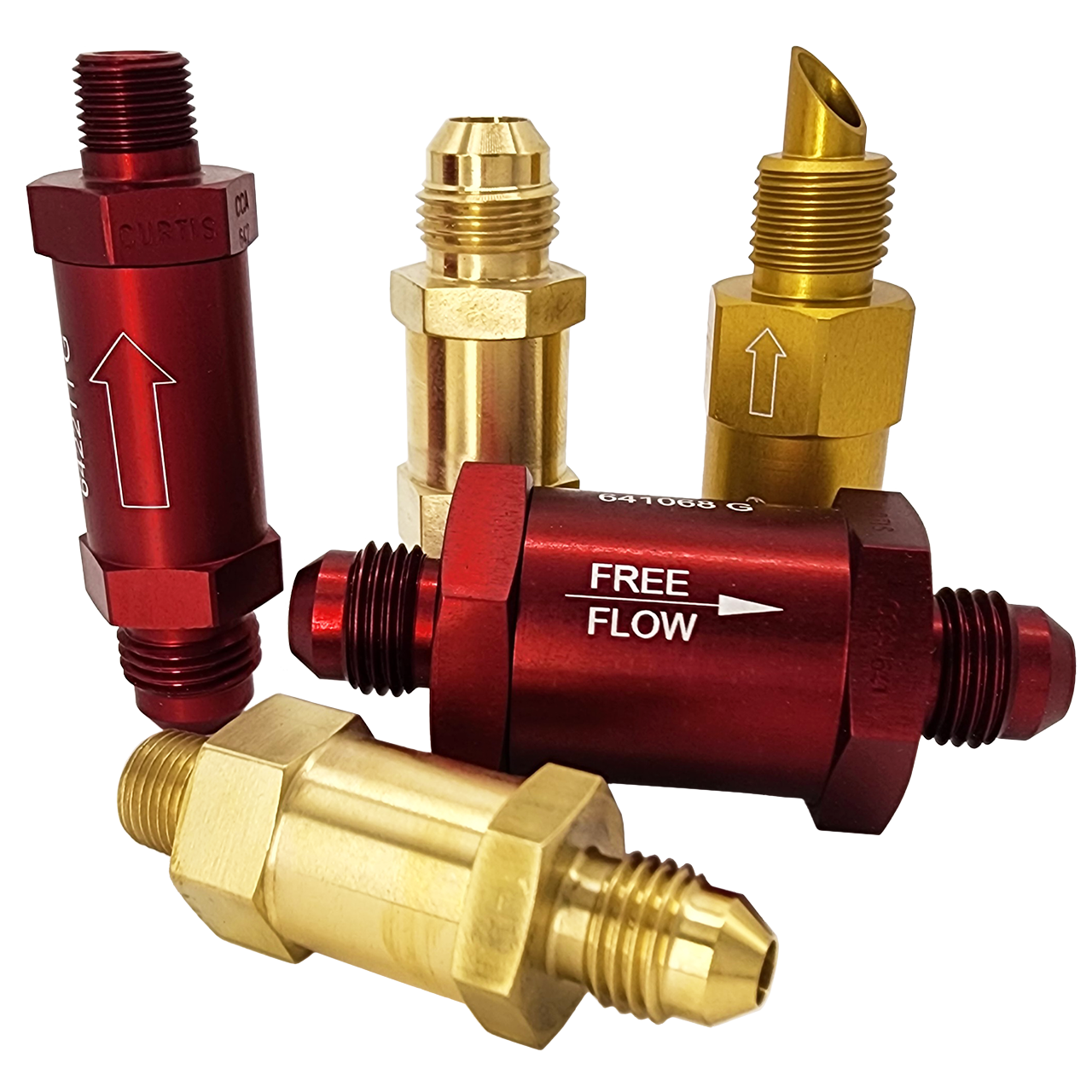

Check Flapper, Free-Flow Drain Valves

Two port, One way valves

Quick Drain Hose Security System & Tools

Drain locks, sample cup

ATV/UTV Oil Drain Valves

Polaris and Can-Am models

Our Products & Aircraft Fuel System Parts

Curtis Valves makes a wide range of valves to solve a wide range of problems. We have over forty (40) standard valve designs engineered, manufactured and tested to exacting specifications. All manufactured in the U.S.A..

Our valves have aerospace, military and industrial applications, and most are listed as ‘Qualified Products’ by the Air Force, Army, Navy and the FAA. Our Quality Systems are compliant and meet International Standard ISO 9001, Military Standard Mil-I-45208, FAA TSO-C76 and FAA-PMA.

The Quick Drain Valve OG

Curtis Valves standard designs are spring loaded closed. Valve springs are made from non-corrosive, long lasting stainless steel. Valve bodies and moving parts are manufactured to precise standards with low tolerances and are available in anodized aluminum, brass, cadmium plated brass, and stainless steel. Most seals are made of a specially compounded “cure dated” synthetic rubber to withstand a wide variety of liquids over a broad temperature range. Our valves use a wedge seal design which help to prevent leakage and improve seal life. All oil drain valves use a Viton compound, for long life in high temp. applications.

Curtis Valves is experienced in valve design and can help solve your valve problems. In most cases, a standard Curtis Valves will do the job, or a slight modification of a production unit will answer a specific problem. We will be glad to give you any assistance you may require with your Quick Drain Valve application!

Maintenance/CMM

Curtis Valves are designed for installation in a standard NPT port for NPT threaded valves or an AND-10050 stlye port for UNF threaded valves. Use a sealant on NPT threaded valves or a fuel resistant o-ring of the proper size for UNF threaded valves. Please refer to aircraft manufacturers torque specifications for the aircraft in which it is being used.

Curtis Valves require no special maintenance. Keep them reasonably clean and replace according to the prescribed synthetic rubber maintenance schedule for the aircraft in which they are used or 10 year usable life per Curtis Valves, whichever occurs first.

Note – Curtis Valves cannot be overhauled with the exception to the valves listed with replaceable O-rings.